Your flotation cells are working exactly as designed.

Unfortunately, they’re designed for ore bodies that no longer represent your biggest profit opportunities.

Your Current Reality

You’re processing increasingly challenging ore that your circuits weren’t designed for:

- Fine particle gold liberation (<20μm) where your conventional flotation struggles

- Carbonaceous gangue stealing dissolved gold from your process

- Complex sulfide matrices resisting your standard cyanidation

Understanding Gold Flotation Fundamentals

Gold flotation is a widely used method for separating gold from ores, particularly when gold is found alongside other minerals like sulfides. The process relies on making gold-bearing particles hydrophobic (water-repelling) so they attach to air bubbles and float to the surface, while unwanted gangue minerals remain in the water phase.

This selective separation works well under ideal conditions – but today’s ore bodies rarely provide ideal conditions.

The Physics Working Against Your Profitability

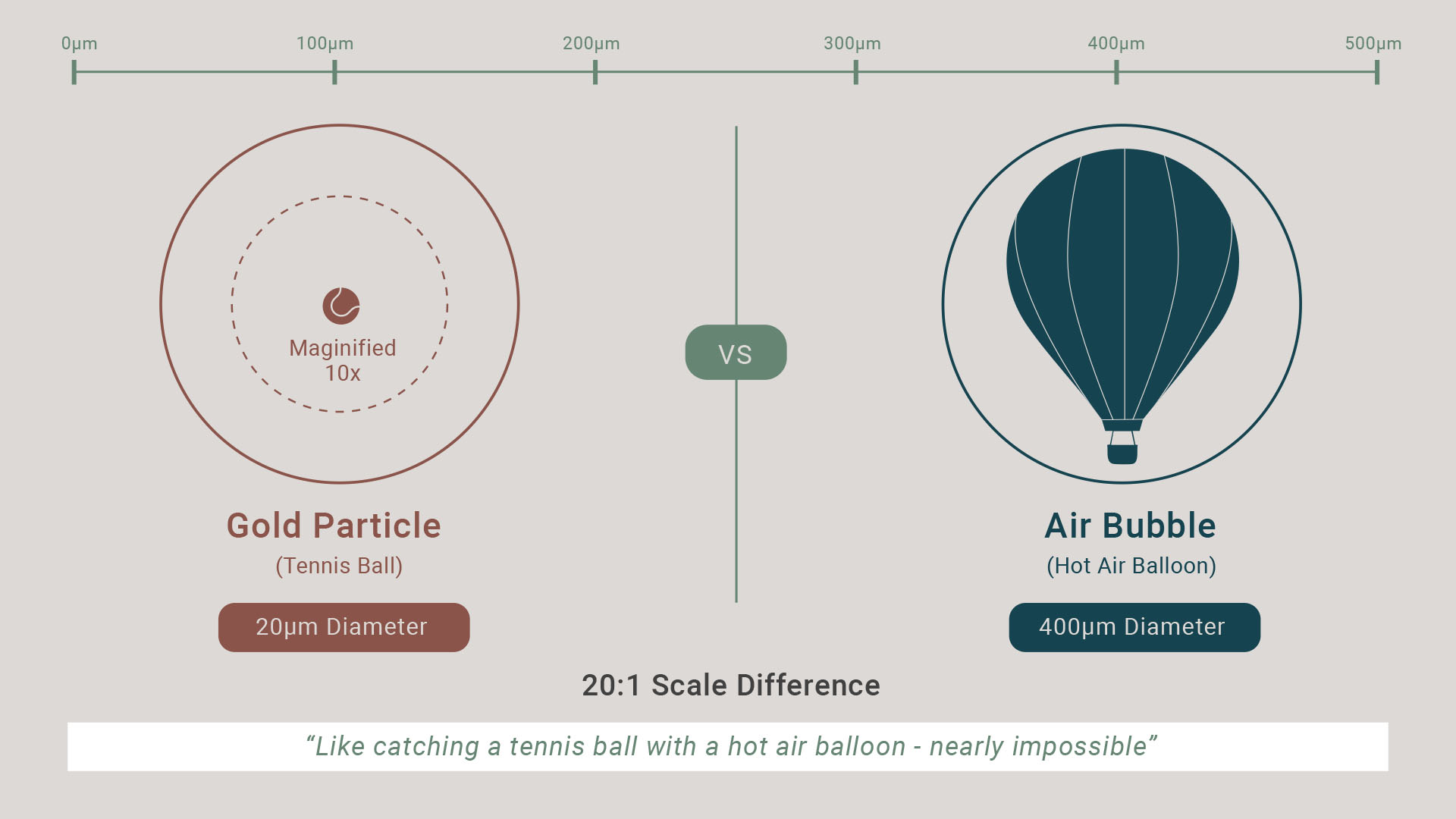

Your flotation relies on particle-bubble collision. Below 20μm, this becomes nearly impossible. The bubble is 20x larger than the particle—imagine trying to catch a tennis ball with a hot air balloon.

Here’s what this costs you: Fine particles have insufficient momentum to penetrate the water layer around air bubbles. They bounce off instead of attaching. Your flotation kinetics drop by 50% or more in the fine fraction (International Journal of Mineral Processing), yet this often represents 40-60% of your total gold losses (Minerals Engineering research).

Add carbonaceous interference, and you’re watching systematic value destruction that conventional flotation optimisation can’t solve.

Your Current Expensive Workarounds

You’ve probably tried solving physics problems with capital expenditure:

- Over-grinding to improve liberation (destroying flotation kinetics further)

- Adding expensive collectors and frothers (marginal improvements at best)

- Installing more flotation cells (longer residence time, same poor kinetics)

- Intensive leaching of flotation concentrates (complex, capital-intensive)

These treat symptoms, not the root cause of your losses. They are compromises that cost money without solving your recovery problem.

Your Pathway to Capturing Lost Value

What if you could bypass the physics limitations entirely for fine particle recovery? What if you could turn your biggest processing challenge into your most profitable operation?

This is exactly why we developed FLeXoR technology.

FLeXoR (Fluidised Leach oXidation Reactors) represents a different processing philosophy for challenging ore types:

- Bypasses flotation kinetics limitations through direct leaching

- Designed for low-grade ores and materials unsuitable for conventional processing

- Operates effectively with particle sizes from fines up to 10mm (dependent on liberation)

- Enables processing of previously uneconomic resources

Our recent gold demonstration plant validated the technology’s commercial viability, achieving recoveries comparable to heap leaching operations while offering reduced capital costs and faster implementation.

Important: FLeXoR suitability depends entirely on specific ore characteristics and operational requirements. We recommend comprehensive ore characterisation and testwork before any investment decision.

Your 2025 Profit Opportunity

At current gold prices, FLeXoR technology could pay for itself in 6-7 months through the improved recovery your operation will achieve. Your biggest technical challenge becomes your fastest payback investment.

Your next step: Understanding why speed of implementation has become critical to maximising these profit opportunities.

Coming up in the series: Why implementing solutions in 12 weeks instead of 24 months could mean the difference between exceptional profits and missed opportunities.

#ProcessInnovation #ProfitOptimisation #RecoverySolutions #FLeXoR